Lincoln® LN-25X® Wire Feeder w/CrossLinc® & Built-In Flowmeter K4267-3

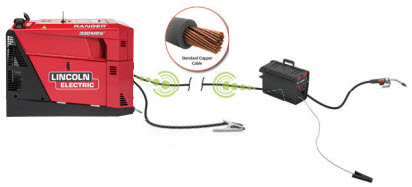

The Lincoln® LN-25X® Wire Feeder with TVT™ and built-in flowmeter is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote-control cable. Built-in CrossLinc® technology allows the LN-25X to communicate directly with a CrossLinc® equipped Lincoln welder through the welding leads, eliminating the need for costly remote-control cables. CrossLinc® remote control distance is limited only by the length of your welding cable leads. CrossLinc® allows your MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage AND amperage control capabilities at the site of the weld without using expensive remote-control cables. The LN-25X can also be used as a traditional voltage sensing feeder on welders not equipped with CrossLinc®

The LN-25X also comes standard with TVT™. True Voltage Technology compensates for voltage drops common with long welding cable runs. TVT automatically detects welding voltage variations and adjust on-the-fly, to provide a smooth consistent arc, even if you are far away from the welder itself.

(Please note: your welder MUST be equipped with CrossLinc® to take advantage of TVT™). The LN-25X wire feeder has up to a 450 amp welding capacity. It features Lincoln's MAXTRAC® wire drive system to ensure smooth wire feeding and excellent electrical contact with your welding gun. It comes complete with built-in flowmeter for remote shielding gas flow control.

Processes

MIG (GMAW)

Flux Cored (FCAW)

Processes

MIG (GMAW)

Flux Cored (FCAW)

Applications

Construction & Field Erection

General Fabrication

Heavy Equipment

Heavy Fabrication

Structural Fabrication

Features:

CrossLinc® with TVT™ technology -

CrossLinc® uses the existing

weld cable to communicate voltage

control information between the

feeder and Lincoln® CrossLinc® power source. This

eliminates the need for a separate remote-control cable. TVT™ (True Voltage Technology) automatically compensates for voltage drops commonly associated with long welding cable runs.

Built-in flowmeter - For remote shielding gas flow control

Tachometer feedback ensures accurate

wire feed speed

Trigger Interlock Switch Provides

operator comfort for long welds

Maxtrac® Wire Drive System Heavy-duty

cast aluminum wire drive system provides

reliable feeding and durability

Built-in flowmeter - For remote shielding gas flow control

Tachometer feedback ensures accurate

wire feed speed

Trigger Interlock Switch Provides

operator comfort for long welds

Maxtrac® Wire Drive System Heavy-duty

cast aluminum wire drive system provides

reliable feeding and durability

Replaceable and Flame Resistant Case

Protects internal components, easy

to replace

Potted PC Boards For moisture and

corrosion protection

Split Wire Guide - Reduces birdnesting

and allows for easy cleaning no-fuss wire

guide alignment

Bright digital meters for easy viewing even

in bright sunlight

Included Tweco style male connector on

input power cable.

Weld Timers Pre-Flow, Post-Flow,

and Burn Back

Adjustable Wire Run-In Speed

for softer starting

Configurable for English or metric units

Arc Hours Meter

Replaceable and Flame Resistant Case

Protects internal components, easy

to replace

Potted PC Boards For moisture and

corrosion protection

Split Wire Guide - Reduces birdnesting

and allows for easy cleaning no-fuss wire

guide alignment

Bright digital meters for easy viewing even

in bright sunlight

Included Tweco style male connector on

input power cable.

Weld Timers Pre-Flow, Post-Flow,

and Burn Back

Adjustable Wire Run-In Speed

for softer starting

Configurable for English or metric units

Arc Hours Meter

Comes Complete With

LN-25X® voltage sensing wire feeder with CrossLinc® and TVT™ technology

Voltage sensing cable and clamp

Built-in flowmeter