Harris® Inferno® HX-3B HQA-4 Brazing Kit 4400083

The Harris® Inferno® HX-3B brazing and soldering kit is 100% TurboTorch® compatible and brazes up to 2 inch I.D. copper tubing using a "B" acetylene gas cylinder. Inferno's swirl flame technology produces consistently hot target flame brazing temperatures WITHOUT the use of an oxygen tank. The HX-3B comes complete with an Inferno HA-3i and HA-11i brazing tip. Use the HA-3i to braze up to 1/2 inch I.D. copper tubing. The HA-11i can braze copper tubing up to 2 inches in inside diameter.

The Inferno HX-3B comes complete with "B" acetylene regulator, HQA-4 brazing torch handle with quick-disconnect fitting, HA-3i and HA-11i brazing tips, 12 foot acetylene hose with "A" fittings, and cylinder wrench.

Compare to TurboTorch® Extreme™ X-3B

Features

Ideal for HAVC brazing applications. Also works well for soldering and heating applications in the plumbing industry.

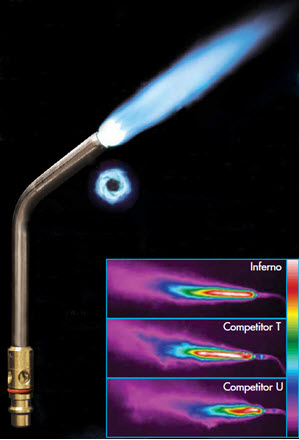

The revolutionary Inferno® tip has a specially designed

insert that delivers reliable swirl combustion

performance every time. The swirl combustion

of the Inferno tip is unlike anything offered

on the market. Contractors get a consistent,

hotter flame that will engulf and wrap

around the work piece for maximum

efficiency.

The technology behind the Inferno® is the result of exhaustive

research and development followed by exacting standards in

manufacturing. The lack of heat, inconsistency and "Horns"

you might find in the flames of other brands are not found in

the flame of the Inferno. With Inferno, you get a richer, hotter, more perfect burn.

Tips take a beating, so the Inferno® is

constructed from thick and strong 304

stainless steel tube stock. All Inferno

tips are crafted from industrial grade

materials designed to stand up in the

field. The Inferno is a tip that is built to last.

Inferno® engineers understand

that the heat contractors need starts with

the precision of the tip orifice. To get

the best flame, Harris has developed a unique

manufacturing process that allows for

consistent production of all Inferno tip

orifices. Harris' exacting manufacturing

standards ensure the optimal delivery of

fuel gas, resulting in the perfect flame.

In addition, during the manufacturing

process, every tip is tested twice, once

to ensure the perfect orifice and once to

ensure flame quality - this all adds up to

making a truly great, hot tip.

Features

Ideal for HAVC brazing applications. Also works well for soldering and heating applications in the plumbing industry.

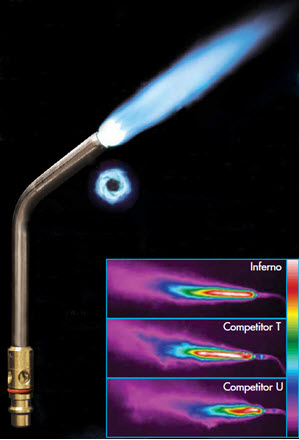

The revolutionary Inferno® tip has a specially designed

insert that delivers reliable swirl combustion

performance every time. The swirl combustion

of the Inferno tip is unlike anything offered

on the market. Contractors get a consistent,

hotter flame that will engulf and wrap

around the work piece for maximum

efficiency.

The technology behind the Inferno® is the result of exhaustive

research and development followed by exacting standards in

manufacturing. The lack of heat, inconsistency and "Horns"

you might find in the flames of other brands are not found in

the flame of the Inferno. With Inferno, you get a richer, hotter, more perfect burn.

Tips take a beating, so the Inferno® is

constructed from thick and strong 304

stainless steel tube stock. All Inferno

tips are crafted from industrial grade

materials designed to stand up in the

field. The Inferno is a tip that is built to last.

Inferno® engineers understand

that the heat contractors need starts with

the precision of the tip orifice. To get

the best flame, Harris has developed a unique

manufacturing process that allows for

consistent production of all Inferno tip

orifices. Harris' exacting manufacturing

standards ensure the optimal delivery of

fuel gas, resulting in the perfect flame.

In addition, during the manufacturing

process, every tip is tested twice, once

to ensure the perfect orifice and once to

ensure flame quality - this all adds up to

making a truly great, hot tip.