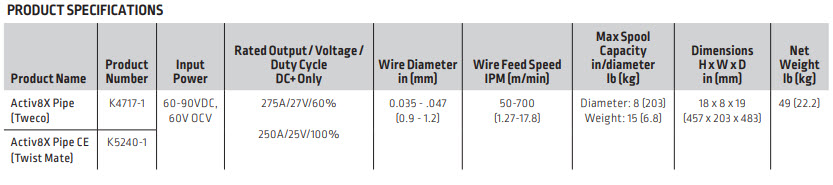

Lincoln® Activ8X® Pipe™ CE Wire Feeder (Twist Mate™/Dinse®) K5240-1

The Lincoln® Activ8X® Pipe™ CE Wire Feeder (Twist Mate™/Dinse®) is an advanced field MIG wire feeder that has pulsed MIG and STT® (Surface Tension Transfer®) capabilities. The advanced features of this feeder also include built-in CrossLinc® technology, which allows the Activ8X Pipe to communicate directly with a CrossLinc® equipped Lincoln welder through the welding leads, eliminating the need for costly remote-control cables. CrossLinc® remote control distance is limited only by the length of your welding cable leads. CrossLinc® allows your MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage AND amperage control capabilities at the site of the weld, without using expensive remote-control cables.

The Activ8X Pipe comes standard with patented Cable View™ technology, which continuously monitors cable inductance and adjusts the waveform to maintain consistent arc performance without the need for an additional voltage sensing lead. The Activ8X Pipe wire feeder has up to a 330 amp welding capacity. It features Lincoln's MAXTRAC® wire drive system to ensure smooth wire feeding and excellent electrical contact with your welding gun.

Processes

STT® (Surface Tension Transfer®)

MIG (GMAW)

Pulsed MIG (GMAW-P)

Flux Cored (FCAW)

Processes

STT® (Surface Tension Transfer®)

MIG (GMAW)

Pulsed MIG (GMAW-P)

Flux Cored (FCAW)

Applications

Construction & Field Erection

General Fabrication

Cross Country Pipe

Process Pipe

Structural Field Welding

Shipbuilding

Features:

Excellent Arc Performance - Perfectly Tuned for Pipe Welding

Optimized arc performance designed specifically for root-to-cap pipe welds, including STT Field and CV/Pulse modes for excellent sidewall fusion, back bead reinforcement, and overall bead profile.

Ultimate Control

Ultimate Control

Full control over the weld process can be easily made right at the wire feeder - no need to waste time walking back to the power supply for adjustments.

Rugged & Portable Design

Built on Lincoln Electric’s proven portable feeder platform, the Activ8X Pipe delivers a lightweight, yet dependable solution that can withstand the extreme conditions of field construction applications.

Straightforward Setup

From truck to ditch, setup is fast and easy. Connection between the Activ8X Pipe and power source is as simple as two standard quick-connect weld cables.

CrossLinc® with TVT™ technology

CrossLinc® uses the existing weld cable to communicate voltage control information between the feeder and Lincoln® CrossLinc® power source. This eliminates the need for a separate remote-control cable. TVT™ (True Voltage Technology) automatically compensates for voltage drops commonly associated with long welding cable runs.

Tachometer feedback

Ensures accurate wire feed speed

Trigger Interlock Switch

Provides operator comfort for long welds

Maxtrac® Wire Drive System

Heavy-duty cast aluminum wire drive system provides reliable feeding and durability

Replaceable and Flame Resistant Case

Replaceable and Flame Resistant Case

Protects internal components, easy to replace

Potted PC Boards

For moisture and corrosion protection

Split Wire Guide

Reduces birdnesting and allows for easy cleaning no-fuss wire guide alignment

Bright digital meters

For easy viewing even in bright sunlight

Included Tweco® style male connectors

Installed on input power cables.

Comes Complete With

Activ8X® Pipe™ CE advanced field wire feeder with CrossLinc® and Cable View™ technology

Input power pigtails with male Twist Mate™ (Dinse®) cable connectors