Miller PipeWorx 400 Welding System Package 230/460V 951000094

Code: 951000094

Miller® PipeWorx™ 400 Welding System Package 951000094

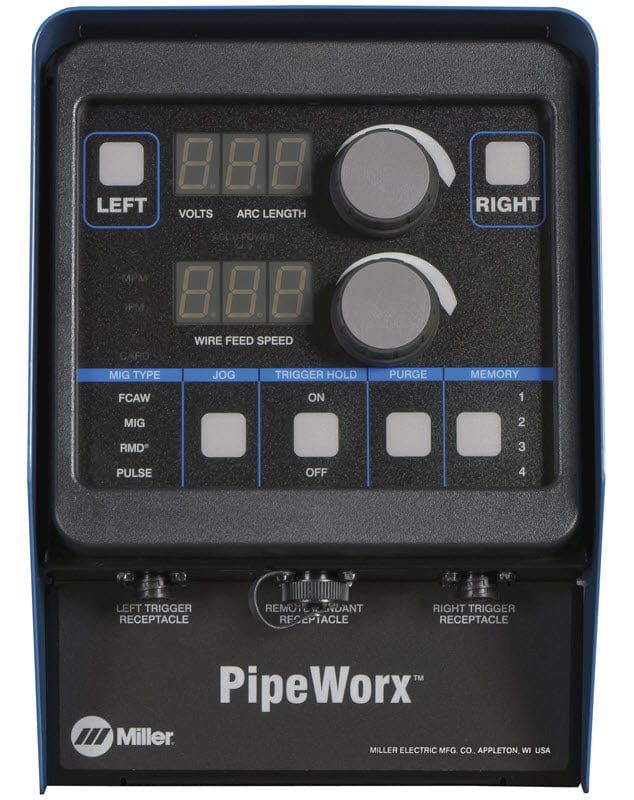

The Miller® PipeWorx™ 400 is a compleate 400 amp multi-process welding solution for your pipe welding fab shop. From root pass to cap pass, the PipeWorx 400 allows you to seamlessly switch between welding processes and/or filler metals. For MIG welding, the PipeWorx Dual-Wire Feeder provides unsurpassed bead control with advanced pulsed-MIG and RMD® (Regulated Metal Deposit®). Left and right MIG gun select allows you to switch back and forth between different filler metals, shielding gases and weld parameters with the touch of a button.

Does your job require stick or TIG welding for any of your pipe welding passes? No problem. The PipeWorx 400 has dedicated stick and TIG welding output studs, so there's no need to disconnect and reconnect OPTIONAL stick welding lead or TIG torch. In stick welding mode, the PipeWorx 400 produces an outstanding arc when using either E6010 or E7018 stick electrodes. For DC TIG, the PipeWorx offers both Lift-Arc™ and high frequencty arc starts. There is also a dedicated TIG shielding gas port on the front panel of the welder. Should your job require a water cooler, a 115 volt outlet is also located on the front panel.

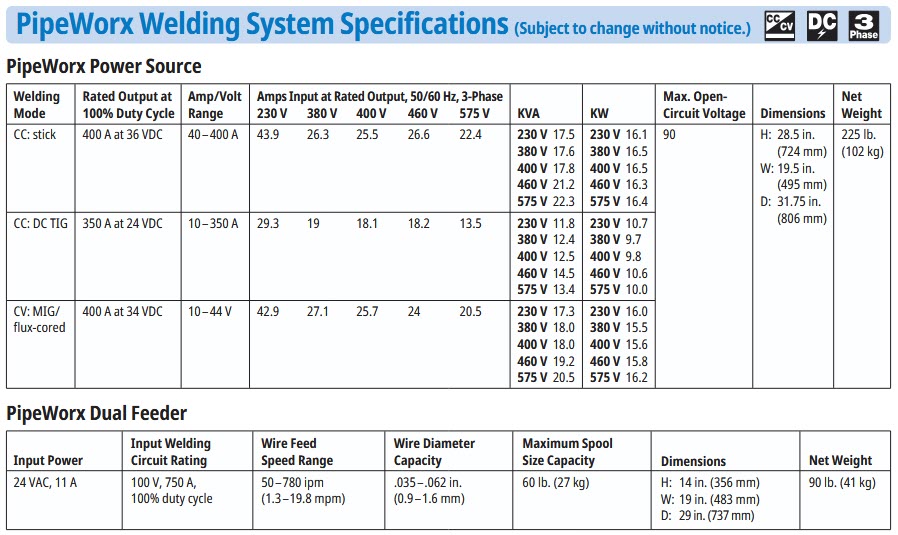

This PipeWorx 400 operates on three-phase, 230/460 volt input power. The included PipeWorx Dual-Wire Feeder comes complete with digital meters, soft keys and memory buttons - plus advanced features like pulsed-MIG, RMD, pre-programmed parameters for advanced MIG welding; plus two MIG gun ports, two sets of drive rolls and spool wire spindles. The complete PipeWorx package includes PipeWorx 400 welder, PipeWorx Dual-Wire Feeder, two Bernard™ PipeWorx 300 amp MIG guns, running gear with dual cylinder rack, two flowmeter/regulators, 25 ft. ground cable with clamp and all interconnecting cables and gas hoses.

Processes

Applications

Heavy Industrial Applications

Process piping

Refinery

Petrochemical

Power plants

HVAC and water pipe

Features

Setting up a new weld process is simple, requiring fewer steps, less training, and minimizing potential errors.

The front panel was designed by welders for welders. Only backlit controls are adjustable to eliminate confusion.

The memory feature stores four programs for stick, DC TIG, and wire processes (left and right feeder side) each.

Innovative cable and gun storage maintains an organized weld-cell area. Cables stay connected to the power source, eliminating the need for switching between welding processes.

All system components are tailored to meet the demands of a pipe fabrication shop

Includes conventional stick, DC TIG (Lift-Arc™ or HF start), flux-cored and MIG welding processes.

Features advanced RMD and pulsed MIG processes for high-quality welds, enhanced productivity, and less rework and training.

PipeWorx ‘Quick-Select’ technology auto-chooses welding process, polarity, cable outputs, and parameters.

Eliminates set-up time for switching cables and gas hoses

Memory card saves process parameters of all memory locations. Each operator can have their own machine settings.

Automatically sets the optimum welding conditions for common E6010 series and E7018 low hydrogen series electrodes.

Provide optimum pipe welding performance. Choose from FCAW, MIG, RMD® and pulsed MIG. RMD modified short circuit and pulsed MIG are synergic programs.

Are optimized based on selection of wire type, wire diameter and shielding gas type. No setting required.

For each selection: stick, TIG, MIG (left and right). This eliminates the need to remember parameters.

Select between high frequency or Lift-Arc™ with the push of a button.

Trigger select allows the welder to select a stored “parameter” without returning to the power source.

Provide system protection in the dusty environment of a pipe shop.

Built-in TIG gas solenoid automatically turns gas on/off in HF or Lift-Arc™ mode.

For water cooler, if used.

Comes complete with

Miller Spool Cover - 12 Inch, Left Side 295321

Genuine Miller® Left Side Spool Cover protects your 12 inch diameter (25 lb./33 lb./44 lb.) spool of welding wire from dust and debris.

Miller Spool Cover - 12 Inch, Right Side 296171

Genuine Miller® Right Side Spool Cover protects your 12 inch diameter (25 lb./33 lb./44 lb.) spool of welding wire from dust and debris.

Miller Reel Cover - 60 lb., Left Side 195412

Genuine Miller® Left Side Reel Cover protects your 50 lb./60 lb. welding wire reel from dust and debris.

Miller Reel Cover - 60 lb., Right Side 091668

Genuine Miller® Right Side Reel Cover protects your 50 lb./60 lb. welding wire reel from dust and debris.

Miller 60 lb. Wire Reel Adapter 108008

Genuine Miller® 60 lb. Wire Reel Adapter allows your Miller wire feeder to accept 50 lb. or 60 lb. coils of solid or cored welding wire.

Miller PipeWorx Composite Cable Kit

Genuine Miller® PipeWorx™ Composite Cable Kit allows you to locate your PipeWorx Dual-Wire Feeder up to 50 ft. away from your PipeWorx 400 multi-process welder.

Miller PipeWorx Cooler 300370

Genuine Miller® PipeWorx™ Cooler is a 3 gallon water coolant system that bolts directly to the bottom of your PipeWorx™ 400 multi-process welder.

Miller PipeWorx Remote Feeder Interface w/Cable 300597

Genuine Miller® PipeWorx™ Remote Feeder Interface provides full remote control of your PipeWorx Dual-Wire Feeder.

Miller PipeWorx Feeder On Power Source Cable Kit 300367

Genuine Miller® PipeWorx™ Feeder-On-Power-Source Cable Kit connects your PipeWorx Dual-Wire Feeder to your PipeWorx 400 multi-process welder, when your feeder is mounted on top of the machine.