Lincoln® Flextec® 350X PowerConnect® / DLF-82 Ready-Pak® K5336-4

The Lincoln® Flextec® 350X PowerConnect® / DLF Ready-Pak® is a complete 350 amp multi-process welder / wire feeder package that is optimized for pulsed MIG welding. The system includes a Flextec 350X PowerConnect® multi-process welder - which is capable of MIG, Pulsed MIG, Flux-cored, DC TIG and Stick welding. It also comes standard with a DLF-82 digital wire feeder with ArcLink®, and Magnum® PRO Curve™ HDE™ 350 MIG welding gun. Built-in ArcLink® technology improves the communication between the feeder and the welding power source, resulting in quicker response times and better welds.

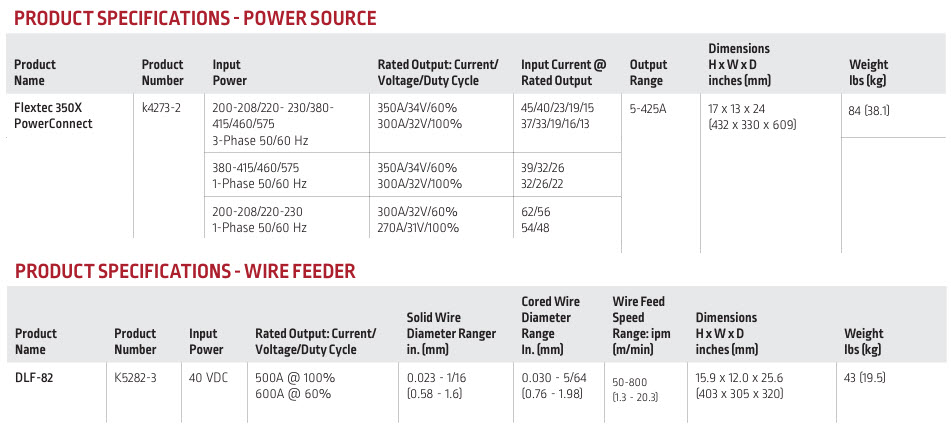

The Flextec 350X PowerConnect® is built to be a rugged performer on the harshest job sites. It is rated IP23 for welding in outdoor weather conditions. The 350X also comes with Lincoln's Desert Duty® certification, meaning it can keep welding in temperatures up to 131 degrees F. Heavy duty alloy carrying handles, powder-coated aluminum case and shock absorbing rubber feet make this an impact resistant power source that will stand up to abuse. The Flextec 350X PowerConnect operates on virtually any electrical power in the world, 200-575 volt, single or three-phase. It comes with Tweco®-style cable receptacles and Lincoln's five-year warranty.

The DLF-82 bench wire feeder is specifically designed for advanced pulsed MIG welding, with simple user interface. The wire reel stand supports up to 60 lb. spools of welding wire. The DLF-82 is rated at 600 amps @ 60% duty cycle and can handle welding wires up to 5/64" diameter. It features Lincoln's MAXTRAC® wire drive system, to ensure smooth wire feeding and excellent electrical contact with your welding gun. It comes complete with Magnum® PRO Curve HDE 350 amp MIG gun with 15 foot leads and .035/.045 drive rolls for solid wire.

Processes

MIG (GMAW)

Pulsed MIG (GMAW-P

Flux-Cored (FCAW)

DC TIG (GTAW)

Stick (SMAW)

Air-Carbon Arc Gouging (CAC-A)

Applications

Fabrication

Construction

Shipbuilding

Structural

Features

DLF-82 bench wire feeder with ArcLink® Included in Package

Simple System Configuration – Includes integrated 5-pin ArcLink® control cable, 0.035/0.045 drive rolls, wire reel stand for up to 60-lb spools, Magnum® PRO Curve™ HDE 350.

Simple to Use – Synergic weld modes for easy one knob control. Set Wire Feed Speed and Voltage is automatically adjusted.

Pulsed MIG Support – with pulse supporting Flextec power source – lower spatter, greater puddle control.

Auto Settings – run-in speed, pre-flow, post-flow, burn-back are auto-set based on setup configuration.

Memories – up to four stored weld schedules for easy changes between different welds

Limits/Lockouts – reduces chance of accidental welding out of procedure

Customizable Start and Crater Settings – greater control over weld profile at start and end of weld.

Includes 15 ft. Magnum® PRO Curve HDE 350 MIG Gun

Optimized arc performance designed specifically for MIG and pulsed MIG welding applications.

Maxtrac® Wire Drive System Heavy-duty

cast aluminum wire drive system provides

reliable feeding and durability

Flextec® 350X PowerConnect® Multi-Process Power Source for all Your Welding Needs

Flextec® 350X PowerConnect® Multi-Process Power Source for all Your Welding Needs

Optimized stick welding for both cellulosic and low hydrogen electrodes.

Touch-Start TIG® for reducing contamination during starts without high frequency.

Compatible with ArcLink® digital feeders, CrossLinc® and 42V analog, and GMAW and FCAW.

Performs STT™ (Surface Tension Transfer) when paired with a Lincoln Activ8X™ pipe wire feeder.

Performs pulsed-MIG welding when paired with a Lincoln ArcLink® digital wire feeder

ArcLink® Technology

Replaces traditional feeder control cable with a high-speed, extremely efficient ArcLink® control cable.

Faster communication between the feeder and welder improves response time, resulting in better welds.

Software Update Capabilities

Software Update Capabilities

Software updates available via USB.

Field Proven Ruggedness and Durability

Engineered for outdoor use and harsh environments.

IP23 rated for use in outdoor weather conditions.

Desert Duty rated for operation at temperatures up to 55° C (131° F).

Trayed and potted PC boards to help withstand welding dust and humidity.

Smart fans run at variable speeds to keep internal machine components cool.

Tough alloy handles for lifting and impact protection.

Lightweight aluminum powder painted case for rust protection.

Shock Absorbing Rubber Feet for impact protection

PLEASE NOTE: This is a DC TIG welder ONLY. It CANNOT TIG weld aluminum.

Comes complete with

Flextec® 350X PowerConnect® Multi-Process Welder with Tweco®-style receptacles

DLF-82 semiautomatic wire feeder K5282-3

8 ft. ArcLink™ connecting cableWork Lead 2/0, Tweco® to GC500, 15ft. K4835-2/0-15

Magnum® PRO Curve™ HDE™ 350 Welding Gun - 15 ft.

Drive Roll Kit Combination .035 in / .045 in Solid Wire KP1696-1

Copper Plus® Contact Tip - 350A, .045 in

Magnum® PRO Nozzle

Flowmeter/Regulator,

355-2AR-580110Inverter cart with single cylinder rack K3059-1

DLF mounting bracket