Miller® AlumaPower™ 350 MPa MIG Welder 907420

The Miller® AlumaPower™ 350 MPa is a 425 amp MIG welder that is specifically designed for pulsed MIG welding of aluminum. When paired with the OPTIONAL XR-AlumaFeed™ wire feeder, the 350 MPa produces aluminum MIG welds that rival the quality and appearance of TIG welds. Built-in MIG and pulsed MIG welding programs allow for easy set up of weld parameters for a variety of welding wires. (Built-in Pulsed MIG programs are available for aluminum MIG wire ONLY)

Processes

- MIG (GMAW)

- Pulsed MIG (GMAW-P)

- Synergic Pulsed MIG

Applications

Industrial Applications

Boat, Ship and Yacht Building

Recreational Vehicles

Trucks and Trailer

Sign Manufacturers

Emergency Vehicles

Features

-

Profile Pulse™ provides TIG appearance with MIG simplicity and productivity. Achieve 'stacked dimes without gun manipulation. Profile Pulse frequency can be changed to increase or decrease the spacing between the ripple pattern to achieve the desired weld appearance.

-

Fan-On-Demand™ cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled through machine.

-

Large, dual digital meters are easy to view and are presettable to ease setting weld output.

-

Inverter arc control technology provides greater puddle control for outstanding MIG and Pulsed MIG weld performance.

-

Auto-Line™ Power Management Technology allows for any input voltage hook-up (208-575 V) with no manual linking required, providing convenience in any job setting. Ideal solution for dirty or unreliable input power.

-

Line voltage compensation keeps welding output constant even if input power varies by +/-10%.

-

Lightweight, aerospace-grade aluminum case offers protection and the benefit of reduced weight.

-

Ultra-tough, polycarbonate-blended cover for control panel protects front controls from damage.

-

Built-in MIG and Pulsed MIG programs - Automatically set the optimal parameters for a wide variety of wires making it easy to setup and use.

-

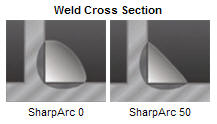

Superior Puddle and Bead Control with SharpArc®. SharpArc controls the arc in Pulsed MIG mode and gives total control over the arc cone shape, puddle fluidity and bead profile. A simple turn of the dial adjusts SharpArc settings, from a wider arc cone with increased fluidity and flatter bead profile to a stiffer puddle with narrower bead.

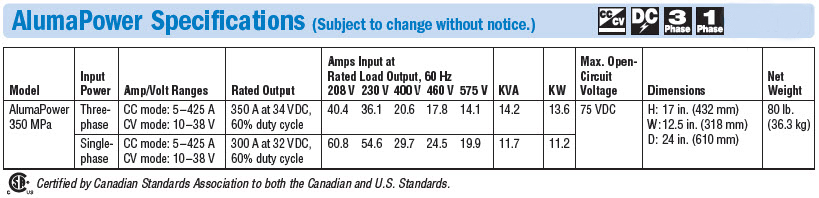

Specs