Miller® ArcReach® SuitCase® 12 Heavy Duty Wire Feeder ONLY 301604

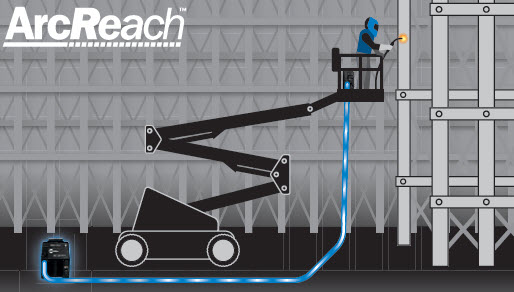

The Miller® SuitCase® ArcReach® 12 Heavy Duty Wire Feeder is a voltage sensing industrial wire feeder that feeds up to 3/32" diameter flux-cored welding wire. The Suitcase 12 HD has full remote voltage and amperage control, without the use of a remote control cable. The secret to this technology is built-in circuitry in both the ArcReach 12 HD feeder and any Miller ArcReach-equipped welder that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage AND amperage control capabilities at the site of the weld, without using expensive remote control cables. The ArcReach® Suitecase® 12 HD MUST be paired with a Miller ArcReach welder to get the full benefits of this feature.

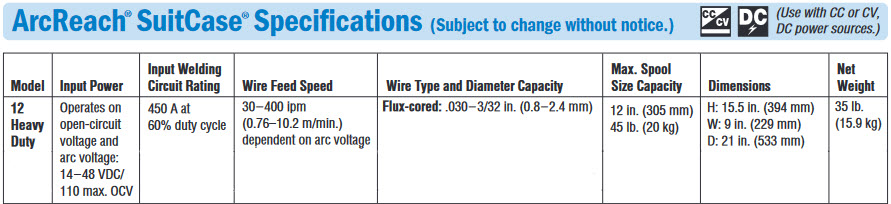

(NOTE: The ArcReach 12 HD wire feeder CAN be used with non-ArcReach welders. However, you WILL NOT have remote voltage control at the feeder)The ArcReach® Suitcase® 12 Heavy Duty wire feeder has a 450 amp welding capacity and handles welding wire spools up to 45 pounds. It is extremely rugged and can be taken just about anywhere. It features an industrial wire feed speed control, wire speed dual schedule and improved wire delivery system. Consistent wire feed speeds and tough polypropylene shell make the SuitCase 12 HD the rugged, reliable choice. It comes complete with 3/32 dia. drive rolls.

Processes

Flux Cored (FCAW)

MIG (GMAW)Applications

Processes

Flux Cored (FCAW)

MIG (GMAW)Applications

Industrial Applications

Shipbuilding

Construction

Heavy Manufacturing

Rental

Features: Full Remote voltage and amperage control of the welding power source without a cord

Full Remote voltage and amperage control of the welding power source without a cord

ArcReach™ technology uses the existing weld cable to communicate welding control information between the feeder and power source. This technology eliminates the need for control cords, and their associated problems and costs.

Portable wire feeding at its best.

The SuitCase 12 HD provides wire feed speed that is accurate and consistent from the start of the weld to the finish, and from one weld to the next. Consistent wire feed speed is very important with large-diameter cored wire, because small changes in wire feed speed make large changes in deposition rates.

Built-in gas valve

For performing MIG and gas-shielded flux-cored welding processes.

Wire delivery system

Bends wire over a large radius and applies just the right amount of force to ensure consistent feeding.

Wire speed dual schedule

Reduces wire speed to 87.5 percent of standard speed. Requires a dual schedule gun or dual schedule switch (sold separately).

Electronic wire feed speed control with integrated tachometer

Ensures wire feed speed accuracy that rivals the best bench top feeders.

Polypropylene case

With built-in slide rails and the ability to open the door to change wire with feeder in vertical position.

Digital meters with SunVision™ technology

Display voltage and wire speed, and also amperage if desired. Meters can be seen clearly even in direct sunlight.

Wider voltage range

For small and large wires with no contactor chatter or arc outages.

Excellent starts and improved superior arc performance

For all types and sizes of flux-cored wires whether using CV or CC power supply.

Potted and trayed main printed circuit board

For the harshest environments adds exceptional reliability. Board has full-trigger isolation so a shorted gun trigger will not affect feeder operation.

Comes Complete With

ArcReach® SuitCase® 12 Heavy Duty voltage sensing wire feeder

Voltage sensing cable and clamp

3/32 VK drive rolls