Miller® FILTAIR® Welding Fume Extractor SWX-S with 12 ft. ZoneFlow™ Arm 951761

The Miller® FILTAIR® SWX-S welding fume extractor with 12 ft. ZoneFlow™ arm captures welding fumes up to five feet from the suction arm. Compare that to conventional fume extractors that can capture welding fumes only 18 inches from the suction arm.

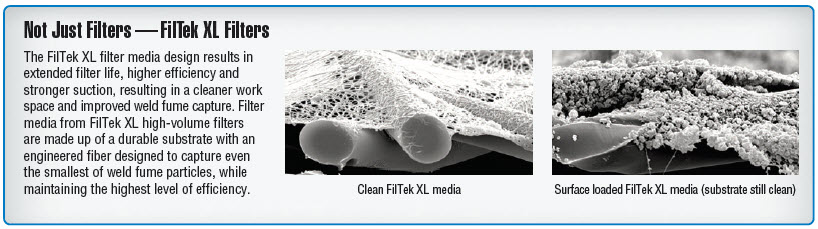

The FILTAIR SWX-S is a wall or column mounted source capture system with self-cleaning FilTek® filter for extended filter life, increased efficiency and cleaner air. Innovative filter cleaning mechanism uses a burst of reverse air flow to clean fume particulates from filter surface. A fast, one minute cleaning cycle is all it takes to remove weld fume particles from the filter. The SWX-S is a stationary system that is intended for industrial welding applications and can operate with multiple extraction arms.. Self-cleaning MERV 15 rated filter traps 95% of all welding fume particulates. The SWX-S's powerful motor and large bell-shaped hood combine to move 875 CFM (cubic feet per minute) of air. The system runs on standard 115V input power and is ideal for schools and training facilities, manufacturing and fabrication shops.

Process

Welding Fume Extraction

Process

Welding Fume Extraction

Applications

Heavy Equipment

Manufacturing

Fabrication

Maintenance and

Repair Operations

Features

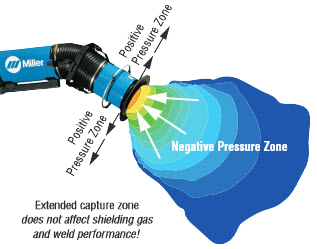

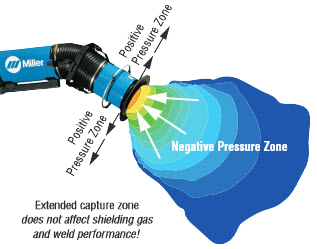

ZoneFlow™ Technology creates a much larger capture area than existing source-capture products and minimizes arm interactions. The capture zone extends out up to five feet from the vacuum hood, as opposed to only eighteen inches with conventional fume extractors.

ZoneFlow technology creates a negative pressure zone that extends the weld particulate capture distance -

Air moving into the arm is still about 900 CFM. However, ZoneFlow technology also moves clean, filtered air out of the arm at approximately a 90 degree angle which creates a large negative pressure zone. This negative pressure zone forms a type of curtain that funnels the weld fume particulate towards the center of the arm, maximizing capture and extending the capture zone up to five feet deep and four feet wide.

Easy to Operate 12 ft. Extraction Arm - offers reliable and accurate positioning across the full range of motion of the arm, as well as easy adjustment and maintenance to ensure long-lasting operation.

Source Capture - capturing fume at the source is critical to maintaining a clean breathing zone for the welder and keeping the facility clean.

Less Arm Movement - Designed to capture fume in larger weld areas while minimizing interactions with the arm. Providing better protection and more welding.

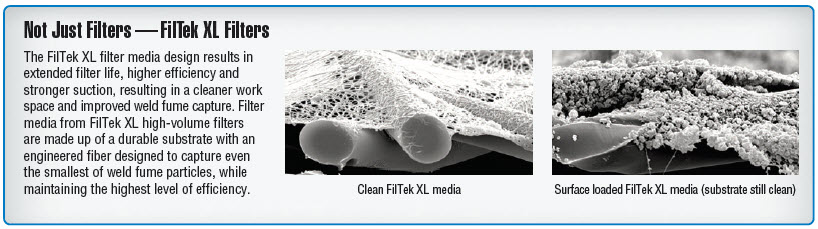

MERV 15 Filter Rating - Filters are rated on a MERV scale, which measures filter efficiency based on particle count. MERV ratings range from 1-16, with 16 being the best at filtering small particles such as those found in weld fumes.

Nanofiber Technology - Nanofibers use an exclusive media blend that features a surface layer of nanofibers about 1000 times thinner in diameter than a human hair.

Self-cleaning mechanism is easy to use. Just push button on control panel to activate the pulse cleaning cycle that cleans the filter from the inside out. Weld fume particulate is removed from the filter and safely deposited in the particulate disposal drawer.

Particulate disposal bin provides easy and convenient access to empty out collected particulate.

Cleaner Air - FILTAIR® fume extractors effectively clean welding fumes from the air. Combining nanofiber filter technology, longer lasting airflow, and an optimized design results in a more powerful fume extraction system.

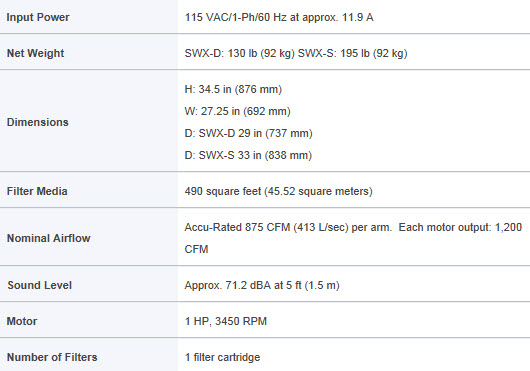

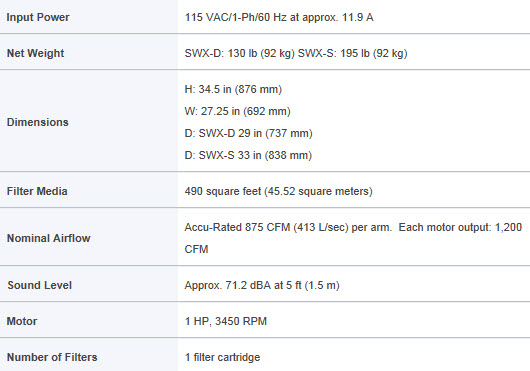

Specs