Miller® Intellx™ Pro Dual Wire Feeder with Bernard® Q400 MIG Gun 951816001

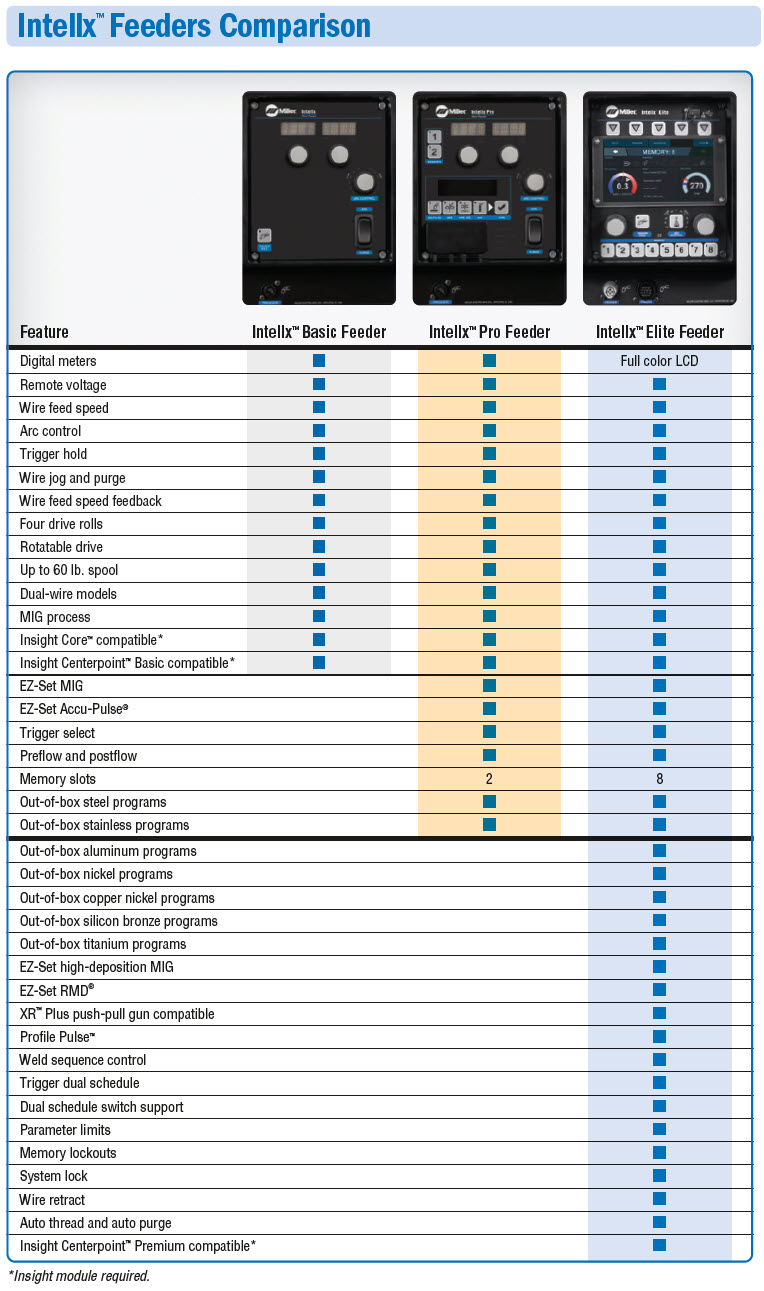

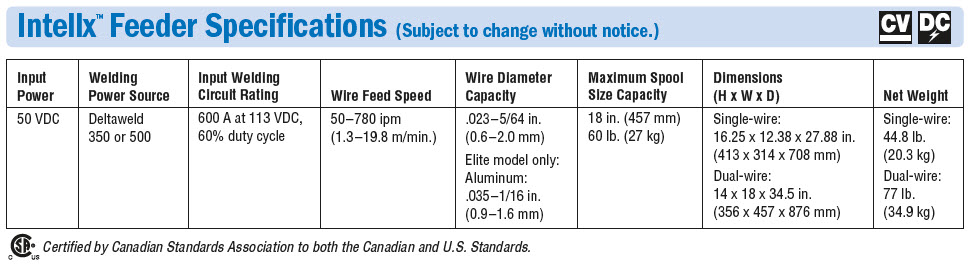

The Miller® Inellx™ Pro Dual Wire Feeder with Bernard 400 amp MIG guns is an industrial 4-roll, pulsed MIG wire feeder that is designed specifically for your Deltaweld® 350 or 500 MIG welder. The Intellx Pro Dual feeder utilizes high speed ArcConnect™ technology, which improves communication and response time between the feeder and the welding power source. The rugged four-roll wire drive system is rotatable, which reduces wire tension and extends MIG gun life.

The Intellx Pro Dual wire feeder comes complete with digital meters, EZ-Set, Accu-Pulse®, memory buttons and steel and stainless weld programs. Other features include: Arc control, for a smoother, more stable arc, wire jog and purge, and wire feed speed feedback.

Complete wire feeder package includes Intellx Pro wire feeder, two Bernard® BTB 400 amp MIG guns and two sets of four .035/.045 V-groove drive rolls.

Processes

MIG (GMAW)

Pulse MIG (GMAW-P)

Accu-Pulse® MIG (GMAW-P)

Flux Cored (FCAW)

Processes

MIG (GMAW)

Pulse MIG (GMAW-P)

Accu-Pulse® MIG (GMAW-P)

Flux Cored (FCAW)

Applications

Heavy Industrial Manufacturing

General manufacturing

General fabrication

Structural steel fabrication

Transportation

Sheet metal fabrication

Light-gauge tube and sheet

Features

Dual-wire models

Allow two different wire types to be available on one feeder, avoiding downtime from changing spools and drive rolls.

Intellx™ Pro Dual feeder - arc control feature means welders can produce better welds with minimal parameter adjustment. Comes standard with Accu-Pulse®, EZ-Set, steel weld programs, and memory buttons.

Intellx Pro available welding programs include:

Steel

Stainless steel

Flux-cored

Metal-cored

Different wire sizes

Different gas types

Balanced-pressure drive-roll design and tensioners

feed wire in its truest and straightest form for consistent feedability, resulting in better welding performance.

Accu-Mate™ connection

aligns the gun perfectly in the drive-roll carrier — preventing the gun from being pulled loose and providing consistent wire feeding.

Drive rolls and guides are common with other Miller® industrial feeders

(use existing, not new parts).

Inlet guide and intermediate guide installation is toolless.

Rotatable drive assembly

allows operator to rotate the drive, eliminating severe bends in the wire feed path. This extends gun-liner life and aids in feeding difficult wires.

ArcConnect™ - is a next generation communication that utilizes high speed signals to improve weld performance and allow point-of-use controls to be located at the feeder.

Comes complete with

Intellx™ Pro Wire Feeder

2 - Bernard™ BTB 400 amp MIG guns

2 - sets .035/.045 in. V-groove drive rolls

FREE Miller® T94i™ ClearLight™ 2.0 auto-darkeing welding hood