Miller XMT 400 ArcReach 6-Pack Rack Fused 460/575 907883

Code: 907883

Miller® XMT® 400 ArcReach® Multiprocess Welder 6-Pack Rack 907883

The Miller® XMT® 400 ArcReach® 6-Pack Rack is a completely assembled system of six 400 amp multi-process welders, installed in a heavy-duty rack. Each welder has an independent power disconnect, with dedicated 460/575 volt fuses. The entire rack features a single electrical connection for 3-phase input power. The rugged steel rack is constructed with two lifting eyes and a heavy-duty skid for moving the 6-Pack around the jobsite.

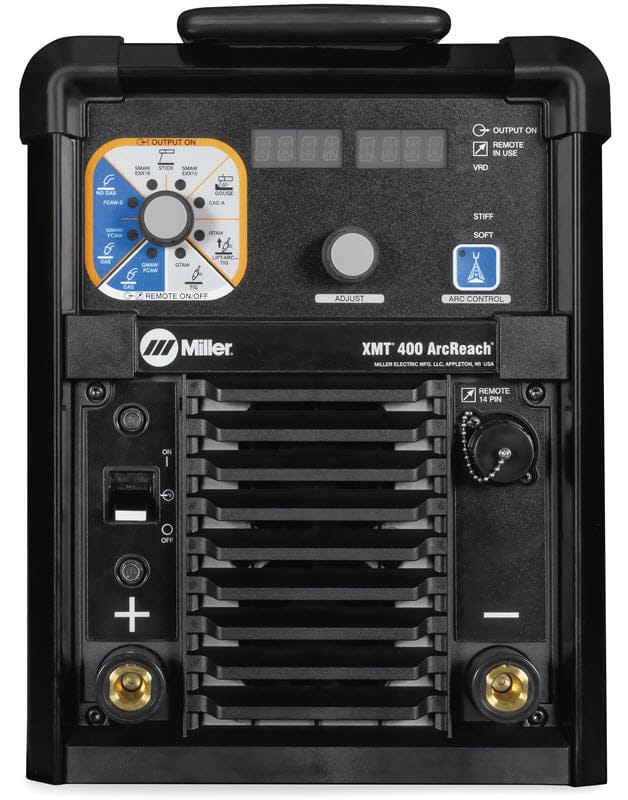

The Miller® XMT® 400 ArcReach® is a portable 400 amp multi-process welder that weighs just 75 pounds. This welder communicates with a remote Miller® ArcReach® wire feeder or Stick/TIG remote without the use of a remote control cable. The secret to this technology is built-in circuitry in both the XMT 400 ArcReach welder and OPTIONAL ArcReach wire feeder/remote that passes remote signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your welding operation to take place further away from the welding power source, and reduces downtime and costs by giving the operator full remote control capabilities at the site of the weld. The XMT 400 ArcReach MUST be paired with a Miller ArcReach feeder/remote to get the full benefits of this feature.

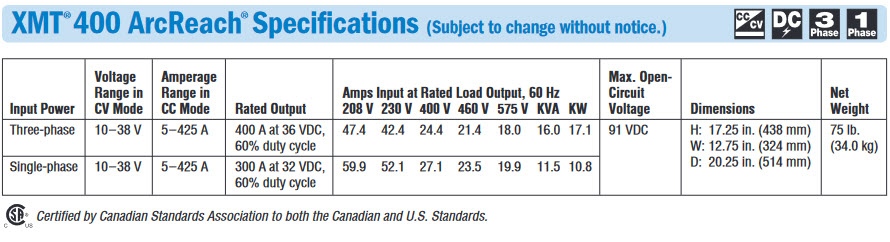

The XMT 400 ArcReach is capable of MIG, pulsed-MIG, Stick and DC TIG welding. It operates on both three-phase and single-phase input power and features Miller's Auto-Line,™ which means you can use 208 volt to 575 volt, single or three-phase input power, without manual linking. Cable Length Compensation (CLC™) automatically adjusts the welder's output to compensate for voltage drops over long welding cable runs - maintaining consistent output current.

The XMT 400 ArcReach is easy to move around the shop or jobsite. Its rugged case design ensures it will stand up to the punishment of extreme work environments. The XMT 400 ArcReach can carbon arc gouge with carbons up to 5/16" diameter. When paired with a wire feeder or spool gun, it makes an excellent MIG and Flux-Cored welder. It also features built-in Lift-Arc™ TIG arc starting for smooth DC TIG arc starts without the use of high frequency.

Processes

* With optional ArcReach® Smart Feeder Only

Applications

Heavy Industrial Applications

Construction

Shipbuilding

Railroad

Truck and Trailer Manufacturing

Fabrication

Repair Shops

Rental Fleets

Features

Comes fully assembled, with welders installed. It comes complete with 460/575 volt fuses.

Eliminate the time spent tracing weld cables hundreds of feet back to the welder. With ArcReach, operators can make adjustments at the ArcReach wire feeder or remote, without the use of costly remote control cables.

Means output is automatically adjusted at the power source to account for voltage drop due to long weld cables, ensuring the operator’s preferred weld parameters.

Are fully supported, enabling operators to use these advanced processes in the field for faster, more efficient welds.

Is made easy with the smallest and lightest machine in its amperage class.

Provides conventional stick, TIG, FCAW, and MIG welding as well as the advanced technologies of RMD and pulse.

ArcReach-equipped welders and wire feeders work with non-ArcReach equipment; however, the complete ArcReach benefit is only realized with the ArcReach system

Provides state-of-the-art flexibility by automatically connecting to 208-575 VAC, single- or three- phase power without removing the covers to re-link the power source. No longer is there a concern if you have the correct machine for the shop or the job site.

Internal air flow that protects electrical components and PC boards from dirt, dust and debris… greatly improving reliability.

Cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled through machine.

Quickly and easily allows the machine to be configured to either Tweco®, Dinse, or Cam-Lok-style receptacles. (Welder ships with Tweco®-style receptacles installed).

Quick, easy adjustments at the wire feeder/remote.

Change weld parameters while the arc is on.

The welder is restored to the previously used weld process and parameter settings once the ArcReach accessory is removed.

Automatically sets the power source to the correct weld process based on the polarity applied to the weld accessory.

Reduces the number of control setup combinations without reducing any features.

Helps promote a fast positive arc ignition helping minimize defects.

Available in the stick and wire modes for easier fine tuning of tough-to- weld materials and out-of-position applications.

Comes complete with

Miller ArcReach Smart Feeder w/Bernard PipeWorx 300 Amp Gun Pkg.

Free

Get a FREE Miller® T94i™ ClearLight™ 4x welding helmet with purchase.

Expires: While supplies last.

See more

Miller® ArcReach® Smart Feeder with Bernard™ PipeWorx™ 300 amp MIG gun package is a portable pulsed MIG and RMD® (Regulated Metal Deposition) wire feeder that is designed to be taken into the field.

Miller ArcReach SuitCase 12 Wire Feeder w/Dura-Flux Gun 951731

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with Bernard® Dura-Flux™ flux-cored gun is a voltage sensing wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach SuitCase 12 Wire Feeder w/Q300 Gun 951729001

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with BTB 300 gun is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Stick/TIG Remote 301325

Miller® ArcReach™ Stick/TIG remote pairs with your Miller ArcReach™ compatible welder to provide full remote amperage control for your stick or TIG welding application without the use of a remote control cable.