Miller XMT 650 ArcReach Polarity Reversing 4-Pack Rack 907852

Code: 907852

Miller® XMT™ 650 ArcReach® Polarity Reversing 4-Pack Rack 907852

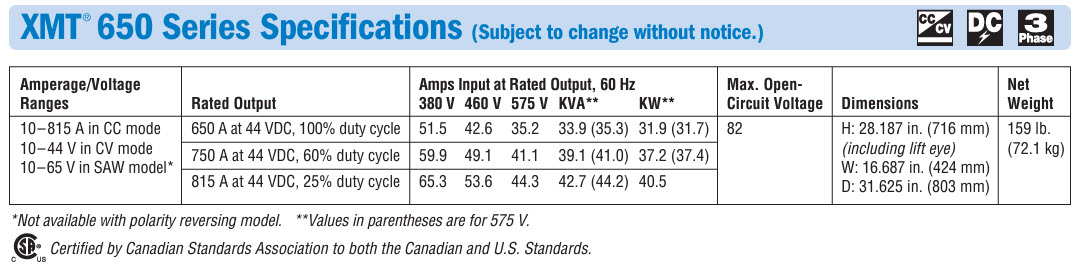

The Miller® XMT™ 650 ArcReach® Polarity Reversing 4-Pack Rack is a completely assembled system of four 650 amp multi-process welders, installed in a heavy-duty rack. Each welder has an independent power disconnect with dedicated 460 volt fuses. The entire rack features a single electrical connection for 3-phase input power. The rugged steel rack is constructed with two lifting eyes and a heavy-duty skid for moving the 4-Pack around the jobsite.

Each of the four XMT 650 ArcReach Polarity Reversing welders feature automatic polarity reversing, based on your welding process. Built-in polarity reversing means you'll never have to spend time switching weld cables, just because you're changing welding jobs. Go from MIG, Flux-Cored, stick, TIG or carbon arc gouging with the turn of of knob. Cumbersome welding cable changeovers are a thing of the past.

The XMT 650 ArcReach Polarity Reversing welders also communicate directly with a remote Miller® ArcReach® wire feeder or Stick/TIG remote, without the use of a remote control cable. The secret to ArcReach technology is built-in circuitry in both the XMT 650 ArcReach welder and OPTIONAL ArcReach wire feeder/remote control, that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage and amperage control capabilities at the site of the weld, without using expensive remote control cables. The XMT 650 ArcReach Polarity Reversing MUST be paired with a Miller ArcReach feeder or ArcReach Stick/TIG remote to get the full benefits of this feature.The XMT 650 ArcReach Polarity Reversing welder is specifically designed for heavy duty welding in the structural steel, building construction and ship building industries. It has a corrosion-resistant aluminum case and is very electrically efficient. The XMT 650 has excellent stick and Lift-Arc™ TIG arc characteristics. It also has superior short-arc MIG characteristics for precise thin metal welding performance. It can perform submerged arc welding, and is also capable of carbon arc gouging with 3/8 inch diameter carbons.

Processes

- MIG (GMAW)

- Stick (SMAW)

- DC TIG (GTAW)

- Flux Cored (FCAW)

- Air Carbon Arc (CAC-A) Cutting and Gouging (through 3/8 in carbons)

- Submerged Arc Welding (SAW)

Applications

Heavy Industrial Applications

Fabrication and construction

Heavy manufacturing

MRO maintenance/repair

Pressure tank/vessel fabrication

Shipbuilding

Refineries and foundries

Rail car manufacturing

Earth-moving equipment manufacturing

Features -

Built-In Polarity Reversing

Streamlined and simplified process changeover eliminates the need for swapping cables. The robust design withstands harsh environments common in the field.

-

Remote control of the power source without a cord

ArcReach™ technology uses the existing weld cable to communicate welding control information between the Miller® ArcReach® feeder or ArcReach® Stick/TIG remote and power source. This technology eliminates the need for control cords, and their associated problems and costs. -

Remote in use indicator

Provides convenient feedback indicating an ArcReach® wire feeder is controlling the power source.

While under ArcReach control, process and voltage/ amperage adjustments are locked out, preventing accidental changes by personnel other than the welding operator. -

Auto Remote Sense™

Enables unit to automatically use remote control if connected to remote control receptacle. -

14-pin receptacle

Has the flexibility to be used with spool guns, feeders, and remote controls. -

Arc control

Is active in the stick and solid-wire processes.

It allows the operator to customize arc characteristics to match preference, electrode and joint design from a softer arc with more fluid puddle to a stiffer arc with a more controllable puddle.

The Star setting is optimized for most applications and pointing the control at Soft or Stiff is optimal for most arc preferences.

Control is fully adjustable from 0 to 25 Soft or 0 to 25 Stiff. -

LED process indicator

Front panel process selections are illuminated with an LED that identifies the active process.

This enables the selected weld process to be seen at a distance from the power source. - Gouging mode is an optimized stick position for better gouging performance

- Three wire modes (GMAW/FCAW/SAW) for simplified setup and optimized arc performance

- Solid and flux-cored wires with gas

- Flux-cored (self-shielded)

- Sub arc - Stick mode for all electrode types

- Lift-Arc™ TIG

Miller ArcReach SuitCase 12 Wire Feeder w/Dura-Flux Gun 951731

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with Bernard® Dura-Flux™ flux-cored gun is a voltage sensing wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach SuitCase 12 Wire Feeder w/Q300 Gun 951729001

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with BTB 300 gun is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Stick/TIG Remote 301325

Miller® ArcReach™ Stick/TIG remote pairs with your Miller ArcReach™ compatible welder to provide full remote amperage control for your stick or TIG welding application without the use of a remote control cable.