Miller® XMT® 350 FieldPro™ Multiprocess Welder (Tweco®) Narrow 4-Pack Rack 907739

The Miller® XMT® 350 FieldPro™ (Tweco®) Narrow 4-Pack Rack is a completely assembled system of four 350 amp multi-process welders, installed in a heavy-duty rack. Each welder has an independent power disconnect, with dedicated 460/575 volt fuses. The entire rack features a single electrical connection for 3-phase input power. The rugged steel rack is constructed with two lifting eyes and a heavy-duty skid for moving the 4-Pack around the jobsite. The rack's narrow profile helps the system fit into tight spaces.

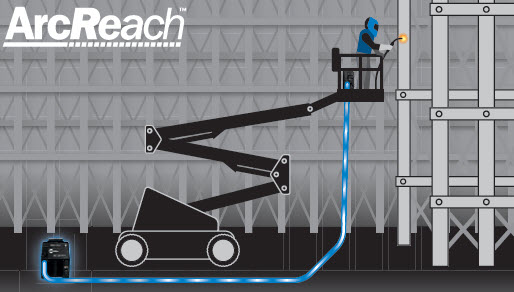

Each of the XMT 350 FieldPro welders communicates with a remote Miller® ArcReach® wire feeder or Stick/TIG remote without the use of a remote control cable. The secret to this technology is built-in circuitry in both the XMT 350 FieldPro welder and ArcReach wire feeder/remote that passes remote signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your welding operation to take place further away from the welding power source, and reduces downtime and costs by giving the operator full remote control capabilities at the site of the weld. The XMT 350 FieldPro MUST be paired with a Miller ArcReach feeder/remote to get the full benefits of this feature.

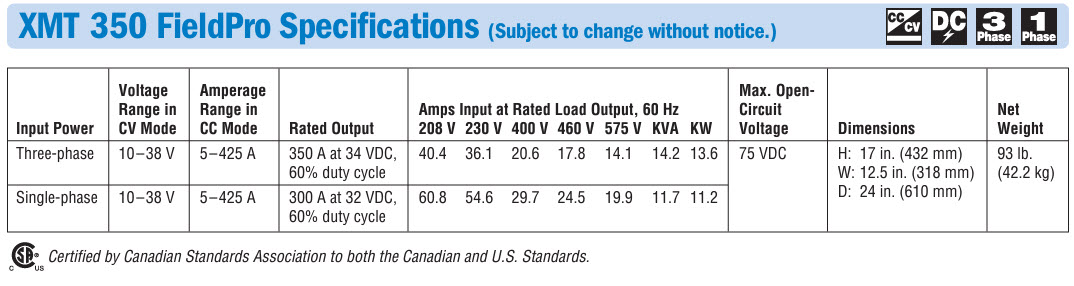

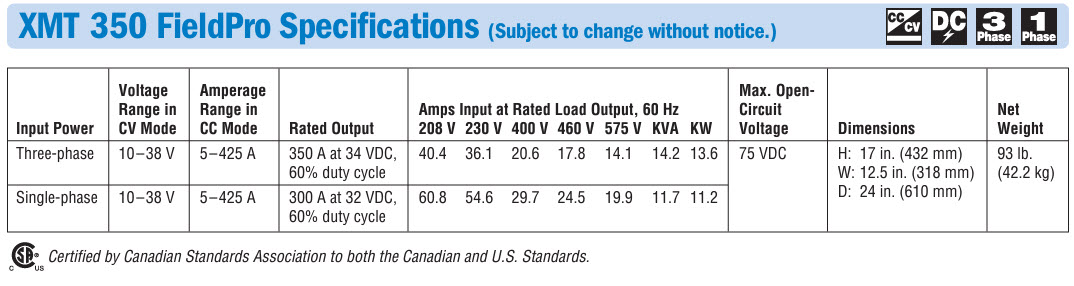

The XMT 350 FieldPro is capable of Pulsed-MIG, MIG, stick and DC TIG welding. It operates on both three-phase and single-phase input power and features Miller's Auto-Line,™ which means you use 208 volt to 575 volt, single or three-phase input power without manual linking.

Weighing just 93 pounds, the XMT 350 FieldPro is easy to move around the shop or jobsite and its rugged case design ensures it will stand up to the punishment of extreme work environments. It is ideal for industrial applications. It is able to carbon arc gouge with carbons up to 5/16" diameter. When paired with a wire feeder or spool gun, the XMT 350 FieldPro makes an excellent MIG and Flux-Cored welder. It's got built-in Lift-Arc™ TIG arc starting for smooth DC TIG arc starts without the use of high frequency.

Processes

MIG (GMAW)

Pulsed MIG* (GMAW-P)

Regulated Metal Deposit* (RMD®)

Stick (SMAW)

DC TIG (GTAW)

Flux Cored (FCAW)

Air Carbon Arc (CAC-A) Cutting and Gouging

* With optional ArcReach® Smart Feeder Only

Applications

Heavy Industrial Applications

Construction

Shipbuilding

Railroad

Truck and Trailer Manufacturing

Fabrication

Repair Shops

Rental Fleets

Features

Multi-operator Narrow 4-Pack Rack

Comes fully assembled, with welders installed. Narrow profile allows the rack to fit into tight spaces. It comes complete with 460/575 volt fuses.

Remote control of the power source without a cord

ArcReach® technology uses the existing weld cable to communicate welding control information between the feeder and power source. This technology eliminates the need for control cords, and their associated problems and costs.

Cable Length Compensation (CLC™)

Makes proper setup of weld parameters faster; automatically adjusting voltage based on weld cable length. This ensures that the voltage a welder operator sets is the voltage they get.

Adjust While Welding (AWW™)

Allows operators to make precise adjustments even while a weld bead is being laid, which allows parameters to be changed while the arc is on.

RMD® and pulsed welding without control cords

Operate up to 200 feet away from the power source with an OPTIONAL ArcReach® Smart Feeder.

Auto-Bind

Automatically establishes an exclusive communication between the power source and the wire feeder, using the existing weld cables upon system power up.

Auto-Line™

Auto-Line™

Provides state-of-the-art flexibility by automatically connecting to 208-575 VAC, single- or three- phase power without removing the covers to re-link the power source. No longer is there a concern if you have the correct machine for the shop or the job site.

Wind Tunnel Technology™

Internal air flow that protects electrical components and PC boards from dirt, dust and debris… greatly improving reliability.

Fan-On-Demand™

Cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled through machine.

Lightweight aerospace-grade aluminum case

Offers protection with the benefit of reduced weight.

New durability standard for field construction.

Designed and built to withstand the harshest field environments.

Tweco®-style weld disconnects

Provide high-quality weld cable connections.

Jobsite mobility is made easy

Small, compact design and Auto-Line technology.

Process selector switch

Reduces the number of control setup combi nations without reducing any features.

Adaptive Hot Start™

Makes starting stick electrodes easy without creating an inclusion.

Infinite arc control

Available in the stick and wire modes for easier fine tuning of tough-to-weld materials and out-of-position applications.

Lift-Arc™

Provides arc starting that minimizes contamination of the electrode and without the use of high-frequency.

True multiprocess system

Provides conventional stick, TIG, FCAW, and MIG welding as well as the advanced technologies of RMD® and pulse.

Fleet compatibility.

ArcReach-equipped power sources and wire feeders work with non-ArcReach equipment; however, the complete ArcReach benefit is only realized with the ArcReach system.

OPTIONAL gas solenoid for TIG welding.

Comes complete with

Fully assembled narrow rack with welders and fuses installed

4 - XMT® 350 FieldPro™ welders with ArcReach® and Tweco® cable receptacles

1,000 feet of 2/0 welding cable