Lincoln Flextec 335XS (Twist Mate) Multi-Process Welding Power Source K4851-1

Code: K4851-1

Couldn't load pickup availability

Lincoln® Flextec® 335XS Multi-Process Welding Power Source (Twist Mate™) K4851-1

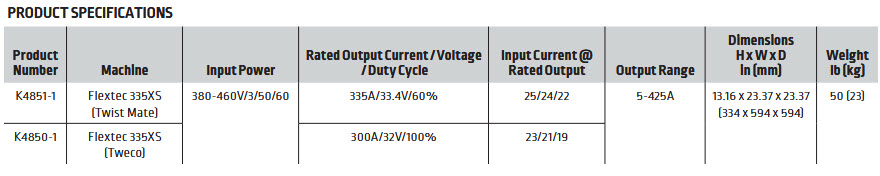

The Lincoln® Flextec® 335XS (Twist Mate™) is a 335 amp multi-process welding power source with CrossLinc®, that is capable of MIG, Pulsed MIG, Flux-cored and Stick welding - when paired with OPTIONAL accessories. This simple, yet powerful power source weighs only 50 pounds. Built-in CrossLinc® technology means that the Flextec 335XS communicates with a REQUIRED (sold separately) CrossLinc remote or Lincoln X Series voltage-sensing wire feeder directly through your welding leads. Full remote amperage and voltage control is achieved without the use of a separate remote-control cable. The Flextec 335XS also supports 5-pin (digital) ArcLink® wire feeders through an amphenol receptacle on the power source.

The Flextec 335XS is built to be a rugged performer on the harshest job sites. It is rated IP23 for welding in outdoor weather conditions. The 335XS also comes with Lincoln's Desert Duty® certification, meaning it can keep welding in temperatures up to 131 degrees F. Heavy duty alloy carrying handle, powder-coated aluminum case and shock absorbing rubber feet make this an impact resistant power source that will stand up to abuse.

The Flextec 335XS operates on 380-460 volt, three-phase input power and comes with Twist Mate™ (Dinse®) cable receptacles and Lincoln's industry leading five-year warranty.

Processes

Applications

Fabrication

Construction

Shipbuilding

Structural

Pipe

Features

(Dinse®-style)

Weighs just 50 lbs for easy transport and maneuverability.

No-front-controls layout reduces failure points and withstands harsh conditions.

Automatically selects the correct weld process based on the connected CrossLinc accessory.

Enabled through ArcLink-compatible feeders for advanced welding control.

CrossLinc® allows for amperage and voltage control at the welding arc to improve control of your operation.

No need for an additional control cable communication occurs directly over the weld cables.

True Voltage Technology™ compensates for voltage drop across the welding circuit.

TVT™ will measure the voltage drop and adjust the power source to compensate for the difference between the desired voltage and actual voltage at the weld.

Ideal for shipbuilding, repair, and field welding.

Backed by a 5-year warranty with no out-of-pocket costs for parts or labor.

Comes complete with

Lincoln CrossLinc Remote K4345-1

Genuine Lincoln® CrossLinc™ Remote for your CrossLink-equipped Lincoln welder ONLY.

Lincoln Activ8X Wire Feeder & Magnum PRO Curve 300 One Pak K3564-1

Lincoln® Activ8X® Wire Feeder with TVT™ and Magnum® PRO Curve MIG Gun is a voltage sensing MIG wire feeder package that has full remote voltage and amperage control without the use of a remote-control cable.

Lincoln Activ8X Pipe Wire Feeder & Magnum PRO Curve HDE 250 One Pak

The Lincoln® Activ8X® Pipe™ Wire Feeder with Magnum® PRO Curve HDE 250 MIG Gun One-Pak® is an advanced field MIG wire feeder package that has pulsed MIG and STT® (Surface Tension Transfer®) capabilities.

Lincoln LN-25X Wire Feeder & Magnum PRO Curve 300 One Pak K4266-1

Lincoln® LN-25X® Wire Feeder w/CrossLinc® and Magnum® PRO Curve 300 MIG gun has full remote voltage and amperage control without the use of a remote-control cable.

Lincoln LN-25X Wire Feeder & K126 PRO 5/64-1/16 One Pak K4266-2

Lincoln® LN-25X® Wire Feeder with CrossLinc® and K126® PRO Innershield® gun has full remote voltage and amperage control without the use of a remote-control cable.

Lincoln Power Feed 25M Wire Feeder (Plastic Case) K2536-5

Lincoln® Power Feed® 25M Wire Feeder (Plastic Case) is an advanced shop or field MIG wire feeder that has pulsed MIG, STT® (Surface Tension Transfer®) and aluminum push-pull welding capabilities.

Lincoln Power Feed 25M Wire Feeder (Aluminum Case) K2536-4

Lincoln® Power Feed® 25M Wire Feeder (Aluminum Case) is an advanced shop or field MIG wire feeder that has pulsed MIG, STT® (Surface Tension Transfer®) and aluminum push-pull welding capabilities.