Miller Big Blue 400 Pro (Kubota) Diesel w/Wireless Interface Control

Code: 907732013

Miller® Big Blue® 400 Pro Kubota® Diesel Welder With ArcReach® and Wireless Interface Control 907732013

The Miller® Big Blue® 400 Pro Kubota with ArcReach® and Wireless Interface Control is a low speed, EPA compliant compact diesel welder with full remote front panel access; including remote amp/voltage control and engine start/stop. The wireless interface control is a handheld unit that controls all weld parameters, stores custom weld settings, displays real time engine status and service intervals, and acts as a remote engine start/stop. Wireless interface control saves fuel, reduces jobsite noise, and enhances worker safety and productivity by reducing trips back and forth to the welder.

The Big Blue 400 Pro is ideal for construction, piping and fleet use. It packs up to 400 amps of welding output at 100% duty cycle and provides 12,000 peak watts of auxiliary power. It is capable of carbon arc gouging using up to 1/4" diameter carbons. When paired with the appropriate wire feeder, it can perform MIG, and flux-cored welding operations. The Kubota® V1505, four-cylinder, liquid-cooled diesel engine is EPA Tier 4F compliant and is engineered to operate over 10,000 hours before the first basic overhaul.

The Big Blue 400 Pro also comes standard with Miller ArcReach®. The ArcReach feature allows the Big Blue to communicate with a remote Miller® ArcReach® wire feeder or ArcReach® Stick/TIG remote without the use of a remote control cable. The secret to this technology is built-in circuitry in both the Big Blue 400 Pro welder and Miller ArcReach wire feeder/remote control that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your Stick, TIG, MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote control capabilities at the site of the weld without using expensive remote control cables. The Big Blue 400 Pro MUST be paired with a Miller ArcReach feeder or ArcReach Stick/TIG remote to get the full benefits of this feature.

Processes

Applications

Mechanical Contractors

Structural Steelwork

Fabrication

Maintenance

Repair

Rental

Construction

Features:

View engine status, fuel level, and battery charge level of remote.

View and select between all available processes.

Turn contactor on/off manually in remote welding mode. Turn engine on/off with remote.

Save custom presets in up to four programs and easily switch between pre-programmed settings.

Quickly adjust and save arc control settings including DIG, DIG range inductance and Auto-Stop.

Adjust amperage or voltage, by increments or percentage, while welding.

Four preset DIG settings (Stick)

Hot Start™ (Stick)

Lift-Arc™ TIG with Auto-Stop™ and Crater-out

MIG/FCAW arc performance

Fuel gauge

Hour meter function

Oil change interval

High coolant temperature and low oil pressure shutdowns

Low fuel shutdown - engine shuts down before system runs out of fuel, making restarts easy.

Digital preset weld meters

Output contactor control

Automatic idle

120 V block heater

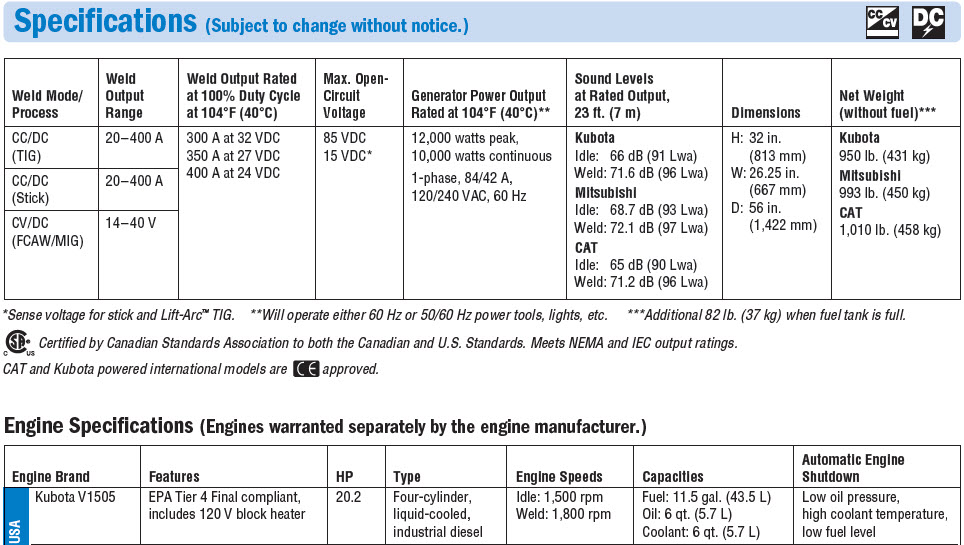

Specs

PLUS get a FREE 500 ft. reel of 2/0 neoprene jacketed welding cable with the purchase of this Miller® Big Blue® 400 welder. While supplies last. (No substitutions allowed.)

Kalas ToughFlex™ 2/0 welding cable, in 500 foot reel, is premium, neoprene jacketed, 600 volt copper cable designed to stay flexible, even in cold weather. Cable is marked in one foot increments for the entire length of the reel.

Miller Big Blue 400 Pro/400 PipePro/450 Duo CST Protective Cover 195301

Genuine Miller® protective cover for your Big Blue® 400 Pro, Big Blue® 400 PipePro® or Big Blue® 450 Duo CST diesel welder.

Miller ArcReach Smart Feeder w/Bernard PipeWorx 300 Amp Gun Pkg.

Free

Get a FREE Miller® T94i™ ClearLight™ 4x welding helmet with purchase.

Expires: While supplies last.

See more

Miller® ArcReach® Smart Feeder with Bernard™ PipeWorx™ 300 amp MIG gun package is a portable pulsed MIG and RMD® (Regulated Metal Deposition) wire feeder that is designed to be taken into the field.

Miller ArcReach SuitCase 12 Wire Feeder w/Q300 Gun 951729001

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with BTB 300 gun is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Suitcase 8 Wire Feeder w/BTB 300 Amp Gun 951726001

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 8 Wire Feeder with BTB 300 MIG gun is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Stick/TIG Remote 301325

Miller® ArcReach™ Stick/TIG remote pairs with your Miller ArcReach™ compatible welder to provide full remote amperage control for your stick or TIG welding application without the use of a remote control cable.

Miller Wireless Interface Control 288137

Genuine Miller® replacement Wireless Interface Control (WIC) is a handheld unit that controls all weld parameters, stores custom weld settings, displays real time engine status and service intervals, and acts as a remote engine start/stop

Kubota V1505 Diesel Engine Filter Kit 253901

Genuine Miller® Kubota® Filter Kit for your Miller Big Blue® Kubota V1505 equipped diesel welder.