Miller Big Blue 600 Air Pak (Deutz) Diesel Welder w/ArcReach 907750

Code: 907750

Miller® Big Blue® 600 Air Pak™ (Deutz®) Diesel Welder with ArcReach® 907750

The Miller® Big Blue® 600 Air Pak™ with ArcReach® is a 600 amp multi-process welder and 20,000 watt AC generator that is equipped with an Ingersoll Rand® 60 cfm air compressor. The compressor has an independent on/off switch, which allows it to run only when needed - saving fuel and reducing maintenance costs. The 65.7 HP Deutz® TD2.9 L4 diesel engine features a Diesel Oxidation Catalyst (DOC) that requires no exhaust after-treatment maintenance; providing the cleanest, greenest exhaust without the hassle.

The ArcReach feature allows the Big Blue to communicate with a remote Miller® ArcReach® wire feeder or ArcReach® Stick/TIG remote without the use of a remote control cable. The secret to this technology is built-in circuitry in both the Big Blue 600 Air Pak welder and Miller ArcReach wire feeder/remote control that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your Stick, TIG, MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote control capabilities at the site of the weld without using expensive remote control cables. The Big Blue 600 Air Pak MUST be paired with a Miller ArcReach feeder or ArcReach Stick/TIG remote to get the full benefits of this feature.

The Big Blue 600 Air Pak is capable of stick, MIG, Pulsed-MIG, flux-cored and Lift-Arc™ DC TIG welding processes. The AC generator supplies 27,000 peak watts and 20,000 continuous watts of 3-phase auxiliary power. Up to 15,000 peak watts and 12,000 watts of continuous single-phase auxiliary power is also available for operating tools, lights and other jobsite equipment. The BB 600 Air Pak is capable of carbon arc gouging using up to 3/8" diameter carbons.

The Big Blue 600 Air Pak is built for the harshest welding environments. It comes standard with block heater and automatic glow plugs. The heavy duty powder coat with zinc-rich primer protects the welder's sheet metal from rust and corrosion. The Deutz® TD2.9 L4 liquid-cooled, turbo-charged, four-cylinder diesel engine is EPA Tier 4F compliant..![]()

Processes

Applications

Heavy construction

Structural steel

Mining maintenance

Maintenance and repair rigs

Process piping

Features:

30,000-hour life expectancy. Independent on/off control for applications not requiring compressed air — allows greater fuel savings and longer compressor service intervals.

ArcReach® allows you to change weld settings from your ArcReach feeder or remote, saving a trip to the power supply. ArcReach technology uses the existing weld cable to communicate welding control information between the feeder or remote and the power source. This technology eliminates the need for control cords, and their associated problems and costs.

Equipped with DOC (Diesel Oxidation Catalyst) that provides the cleanest, greenest exhaust without the hassle of after-exhaust maintenance.

Improves work site communication.

Simultaneously displays fuel level, engine hours, coolant temperature, oil pressure, battery volts and engine rpm. Also tracks oil change intervals and displays engine diagnostics for quick and easy servicing.

Four preset DIG settings (Stick)

Hot Start™ (Stick)

Lift-Arc™ DC TIG

MIG/FCAW arc performance

Unlike conventional DIG that provides a preset amount of short-clearing current, Miller-exclusive Dynamic DIG technology works on a time-based algorithm that automatically adjusts the amount of current required to clear a short. Delivers a smoother more consistent arc that can be tailored to match application, material, fit-up and welder technique.

Prevents machine damage if the duty cycle is exceeded or airflow is blocked.

Detects if a remote control is plugged into the 14-pin receptacle and eliminates confusion of a remote/panel switch.

When enabled, reduces the open-circuit voltage to 30 volts when the welding power source is not in use, increasing operator safety without compromising arc starts.

Protects sheet metal from rust and corrosion.

Adjustable Hot Start™

Output contactor control

Automatic idle

120-volt block heater

Automatic glow plugs

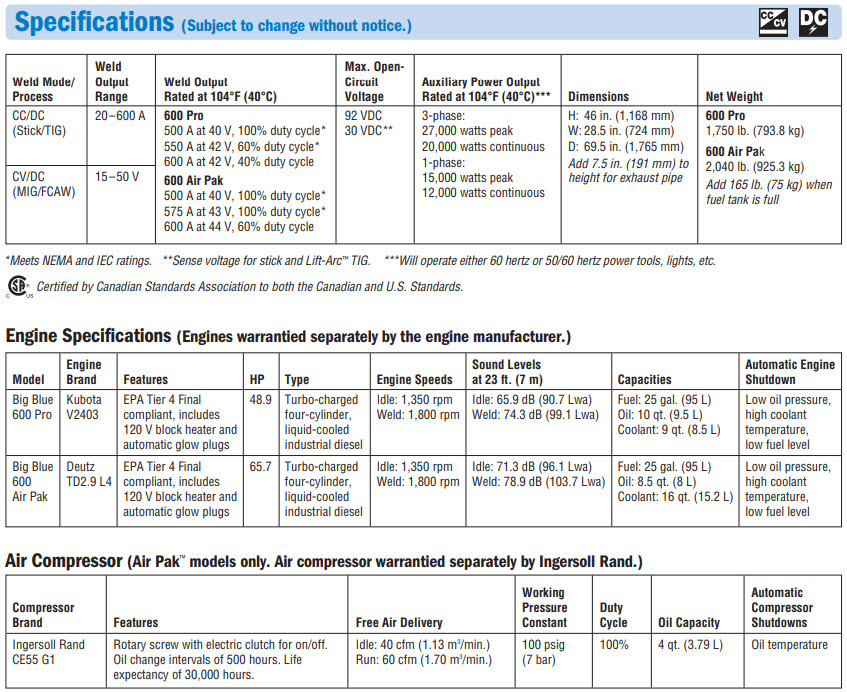

Specs

Miller ArcReach Smart Feeder w/Bernard PipeWorx 300 Amp Gun Pkg.

Free

Get a FREE Miller® T94i™ ClearLight™ 4x welding helmet with purchase.

Expires: While supplies last.

See more

Miller® ArcReach® Smart Feeder with Bernard™ PipeWorx™ 300 amp MIG gun package is a portable pulsed MIG and RMD® (Regulated Metal Deposition) wire feeder that is designed to be taken into the field.

Miller ArcReach SuitCase 12 Wire Feeder w/Q300 Gun 951729001

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with BTB 300 gun is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach SuitCase 12 Wire Feeder w/S-Gun 951730

Free

Get a FREE Miller® Digital Performance™ ClearLight™ 4x welding helmet AND a 10 lb spool of .045 flux-cored wire with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with Bernard® S-Gun™ is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Suitcase 8 Wire Feeder w/BTB 300 Amp Gun 951726001

Free

Get a FREE Miller® Digital Elite™ ClearLight™ 4x welding helmet OR Instant Savings with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 8 Wire Feeder with BTB 300 MIG gun is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Stick/TIG Remote 301325

Miller® ArcReach™ Stick/TIG remote pairs with your Miller ArcReach™ compatible welder to provide full remote amperage control for your stick or TIG welding application without the use of a remote control cable.

Deutz TD2.9 L4 Diesel Engine Filter Kit 262459

Genuine Miller® Deutz® TD2.9 L4 filter kit for your Miller Big Blue® welder equipped with a Deutz TD2.9 L4 diesel engine.