Miller XMT 450 CC/CV ArcReach 907481003

Code: 907481003

Select Your Free Zone Promo Bonus

Miller® XMT® 450 CC/CV Multiprocess Welder With ArcReach™ 907481003

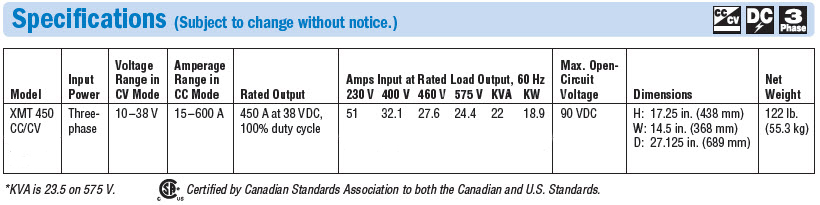

The Miller® XMT® 450 CC/CV with ArcReach™ is a portable 450 amp multi-process welder that communicates with the remote Miller® ArcReach™ wire feeder without the use of a remote control cable. The secret to this technology is built-in circuitry in both the XMT 450 CC/CV ArcReach welder and ArcReach wire feeder that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage and amperage control capabilities at the site of the weld without using expensive remote control cables. The XMT 350 CC/CV ArcReach MUST be paired with a Miller ArcReach feeder to get the full benefits of this feature

The XMT® 450 CC/CV is a 450 amp multiprocess welder capable of MIG, Stick and DC TIG welding. With a maximum of output of 600 amps, the XMT® 450 CC/CV is heavy duty industrial, inverter welder that is excellent for carbon arc gouging and Flux-Cored Arc Welding.

Applications

Construction

Shipbuilding

Railroad

Truck and Trailer Manufacturing

Fabrication

Repair Shops

Rental Fleets

Power Generation Plants

Features

Miller Inverter MIGRunner Cart 195445

Genuine Miller® Inverter MIGRunner™ Cart for your AlumaFeed™ System, Invision™ 352 MPa, XMT® 304, XMT® 350 or XMT® 400 welder.

Miller ArcReach SuitCase 12 Wire Feeder w/S-Gun 951730

Free

Get a FREE Miller® Digital Performance™ ClearLight™ 4x welding helmet AND a 10 lb spool of .045 flux-cored wire with purchase.

Expires: While supplies last.

See more

Miller® SuitCase® ArcReach® 12 Wire Feeder with Bernard® S-Gun™ is a voltage sensing MIG wire feeder that has full remote voltage and amperage control without the use of a remote control cable.

Miller ArcReach Stick/TIG Remote 301325

Miller® ArcReach™ Stick/TIG remote pairs with your Miller ArcReach™ compatible welder to provide full remote amperage control for your stick or TIG welding application without the use of a remote control cable.

Miller Inverter MIGRunner Cart 195445

Genuine Miller® Inverter MIGRunner™ Cart for your AlumaFeed™ System, Invision™ 352 MPa, XMT® 304, XMT® 350 or XMT® 400 welder.

Miller XMT 450 Gas Valve Kit 300928

Genuine Miller® XMT® 450 Gas Valve Kit for your Miller XMT 450 CC/CV or XMT 450 MPa multi-process welder.